Marine technology - application example

DasyLab can simultaneously visualize and archive 207 variables from the equipment of a semi-submersible

Heavy lift carrier in order to draw up a commissioning report. In Asia, I&S IP 9, the Marine Solutions subdivision

of Siemens AG, makes equipment for the electrical propulsion of semi-submersible heavy lift carriers.

Semi-submersible heavy lift carriers are floating platforms which can partly submerge themselves in the sea

so that their cargo deck is just a few meters below the waterline. Semi-submersible heavy lift carriers are used

for transporting floating vessels such as ships, submarines or parts of oil rigs. In order to place a load on the

semi-submersible heavy lift carrier, the load does not have to be lifted onto the cargo deck with a crane;

the semi-submersible heavy lift carrier partially submerges, the floating vessel positions itself over the submerged

cargo deck and then the semi-submersible heavy lift carrier rises again, lifting the vessel to be transported.

During loading or unloading, it is extremely important that the position of the cargo deck of the semi-submersible

heavy lift carrier is not changed. This is ensured by a DP system (Dynamic Positioning System). Two podded

drives (Siemens Schottel Propulsors - SSP), which are located at the stern and can be rotated through a full 360

degrees, position the semi-submersible carrier longitudinally and transversely while two bow-thrusters enable

transverse positioning.

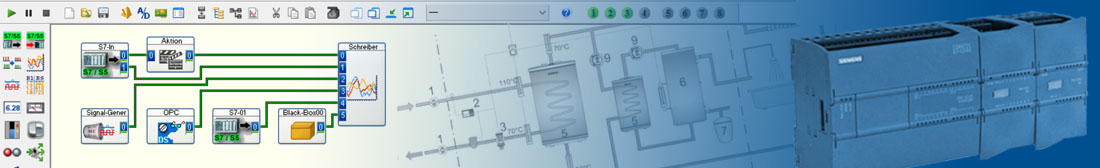

These propellers and bow-thrusters are driven by electric motors, whose behavior is

controlled by SIMATIC S7 control units. Closed-loop control is provided by SIMADYN-D for the SSP propulsors

and by MASTERDRIVE for the bow-thrusters. The desired position is compared with the actual position, whereby

the latter is determined by a DGPS (Differential Global Positioning System). The result is passed on to the

SIMATIC-S7 control units, which then adjust the power output of the relevant electric motors.

The DP system can place the semi-submersible heavy lift carrier exactly in the desired position to an accuracy

of 1 meter. In order to ensure that the semi-submersible carrier retains its position even in choppy water and when

a strong wind is blowing, the electric motors must satisfy specific performance requirements.

This is checked by means of DasyLab.

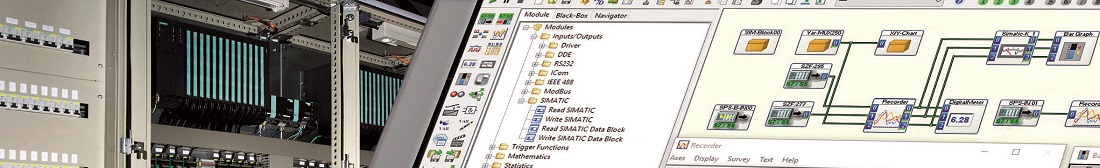

Layouter creates clarity

Via an MPI/PROFIBUS cable, DasyLab reads 207 variables (power intake, temperature, speed, etc.) out

of the corresponding SIMATIC S7 control units simultaneously at a sampling rate of 2 seconds. It then visualizes

and archives these variables. With the Layouter function (available as an option) for DasyLab, the data are displayed

on the screen in a clear and easy-to-understand manner. It is, of course, impossible to display 207 variables at the

same time without causing confusion. The Layouter therefore makes it possible to switch back and forth between

different screen presentations (layouts), which can be printed and given to the customer as a commissioning report.

DasyLab - a convincing solution

DasyLab convinced Mr. Iden (Siemens AG) by its simple method of connection to a SIMATIC S7 and by its

straightforward and clear presentation of measured values using different screen presentations (layouts).